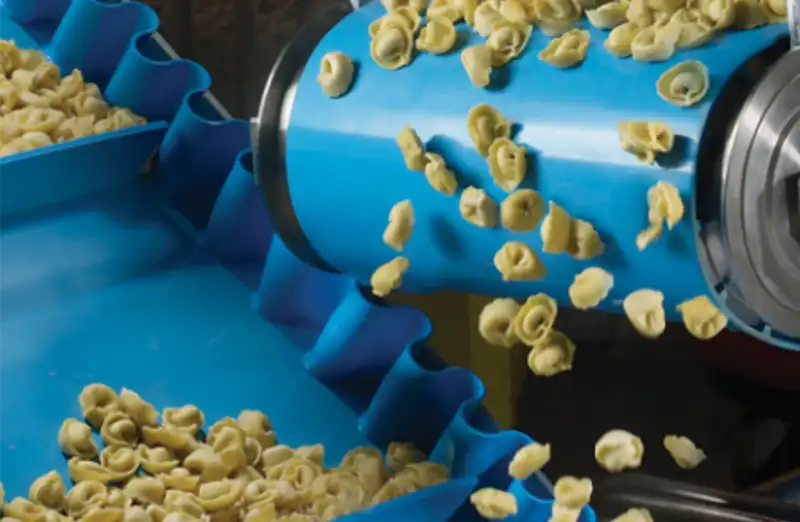

Monolithic belts provide superior form and function to a variety of industries.

Crafted from solid, flexible thermoplastics such as polyurethane, monolithic belts provide longevity and dependability. Compared to traditional rubber conveyors, monolithic conveyor belts more easily withstand abrasive materials. Capable of fitting into endless, fabricated, and special applications, these belts fit into almost any conveying system. Through custom additions and adjustments, monolithic conveyor belts fit into operations that require horizontal, elevator, center drive, trough, or profile belts. Carefully crafted to perfectly fit your application, our monolithic belts provide superior form and function.