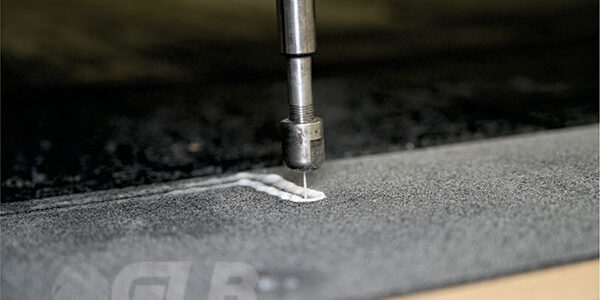

Whether you have heard the term before or not, you may wonder what waterjet cutting is and why it is used alongside custom fabrication when it is talked about. There are different ways to provide custom fabrication, but waterjet cutting comes with its own benefits that you should consider before making a decision on whether or not it is best for your business.

Great Lakes Belting provides this service because of the precision and versatility that it offers with custom fabrication. Essential components need to be manufactured with pinpoint accuracy. Waterjet cutting ensures this accuracy for every project, no matter the specifications.

Efficiency from powerful precision

Precision cuts with waterjet cutting both guarantee a great product at the end of production and create an efficient workplace. It creates no hazardous waste and requires no additional finishing process. Because of their design, waterjet cutters have no need for components that release fumes or gasses into the workplace. And, the precision of their cuts mean products are complete as soon as the process is over. This avoids the need for additional finishing on the metal afterward.

Great for any custom fabrication

Custom fabrication operations choose waterjet cutting over others when they want a process that works with all our belting materials. The process is versatile in that it allows cutting of PVC, Polyurethane, plastics, rubber, composites, and more. Any belting material that a custom conveyor and its components need has this service as an option. And, because it is a cold cutting process, there is no distortion of materials from heat exposure. This creates the finest of cuts without warping the finished product.

With over two decades of experience and a dedication to always serve the needs of our customers, Great Lakes Belting is the right choice for custom fabrication. Learn more about our waterjet cutting services and how they can help you by giving us a call!